Industrial environments are complex, dynamic, and often hazardous places that demand rigorous safety measures to protect workers and maintain operational efficiency. Among the numerous safety features in these settings, handrailing and flooring stand out as fundamental components that can significantly influence the safety and productivity of the workplace. This article delves into the importance of installing the right handrailing and flooring in industrial settings in the UK, highlighting their critical roles in accident prevention, regulatory compliance, and overall operational efficiency.

Safety and Accident Prevention

One of the most pressing reasons for installing appropriate handrailing and flooring in industrial settings is to ensure the safety of workers. Industrial environments are rife with potential hazards such as slippery surfaces, uneven ground, and elevated workspaces. The right flooring can provide traction and reduce the risk of slips, trips, and falls, which are among the most common types of workplace accidents.

Non-slip flooring materials, such as GRP, aluminium, steel, or cast iron, are essential in areas prone to moisture, oil spills, or other slippery substances. These materials provide a stable and secure surface for workers to navigate, significantly lowering the risk of slip-related injuries.

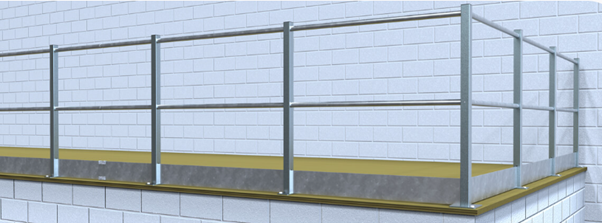

Handrailing is equally important in preventing falls, particularly in elevated work areas like platforms, staircases, and mezzanines. Sturdy handrails offer support and stability, helping workers maintain balance and safely navigate height differences. They are also crucial for preventing accidental falls from raised surfaces, which can result in severe injuries or fatalities.

Enhancing Operational Efficiency

Beyond safety, the right handrailing and flooring can enhance operational efficiency. Smooth, durable flooring facilitates the movement of machinery, equipment, and personnel, reducing the time and effort required to perform daily tasks. For example, in a warehouse setting, floors that can withstand the weight and friction of forklifts and pallet jacks ensure seamless and efficient operations.

Handrailing contributes to efficiency by providing clear pathways and support structures that guide the movement of workers, especially in complex industrial layouts. Well-placed handrails can delineate safe walkways, preventing workers from straying into hazardous areas or interfering with machinery. This organized flow of movement helps maintain a productive and safe working environment.

Compliance with Regulatory Standards

Compliance with occupational health and safety regulations is a non-negotiable aspect of industrial operations. Regulatory bodies such as the Health and Safety Executive (HSE) in the United Kingdom set stringent standards for workplace safety, including specific requirements for handrailing and flooring.

Failing to comply with these regulations can result in severe penalties, including fines, legal liabilities, and even shutdowns of operations. More importantly, non-compliance puts workers at risk and can tarnish a company’s reputation. By installing handrailing and flooring that meet or exceed regulatory standards, industrial facilities can avoid these pitfalls and ensure a safe working environment.

Durability and Longevity

The industrial environment is characterised by heavy use and exposure to harsh conditions, making durability a critical factor in selecting handrailing and flooring. Materials must be chosen not only for their safety features but also for their ability to withstand the rigours of industrial use.

Flooring in industrial settings must endure heavy loads, spills, and constant traffic without degrading. High-quality materials like cast iron, aluminium, steel or GRP, are designed to provide long-lasting performance under these conditions. Similarly, handrails must be constructed from robust materials such as steel or aluminium, which can resist corrosion, impact, and wear over time.

Investing in durable handrailing and flooring reduces the need for frequent repairs or replacements, thereby lowering maintenance costs and minimising downtime. This longevity translates into better financial efficiency and uninterrupted operations.

Customisation and Adaptability

Industrial facilities often have unique requirements based on their specific operations, and the ability to customise handrailing and flooring solutions to meet these needs is vital. Customisation ensures that safety features are tailored to address particular hazards and operational demands.

For instance, in a chemical processing plant, flooring may need to be resistant to corrosive substances, while in a food processing facility, it might require easy-to-clean surfaces that comply with hygiene standards. Similarly, handrails in a warehouse might need to accommodate heavy-duty usage and be easily modifiable to adapt to changing layouts.

The adaptability of these safety features allows industrial settings to evolve and expand without compromising on safety or efficiency. Tailored solutions ensure that safety measures are relevant and effective, providing optimal protection and functionality.

Conclusion

In conclusion, the installation of the right handrailing and flooring in industrial settings is paramount for ensuring worker safety, enhancing operational efficiency, and complying with regulatory standards. These elements are not mere infrastructural components but critical safety features that prevent accidents, support efficient workflows, and provide durable and adaptable solutions to meet the demands of challenging industrial environments.

By prioritising the quality and appropriateness of handrailing and flooring, industrial facilities in the UK can create safer, more productive workplaces that protect their most valuable assets—their workers. Investing in the right materials and designs for these safety features is not just a regulatory or ethical obligation but a strategic decision that can lead to long-term operational success and sustainability.