Stop compromising between strength and corrosion resistance.

F.H.Brundle is your trusted UK stockist for a comprehensive range of Glass Reinforced Plastic (GRP) products, offering a modern, superior alternative to traditional materials like steel and wood for industrial, commercial, and public-sector applications.

Why Choose GRP Products from

F.H.Brundle?

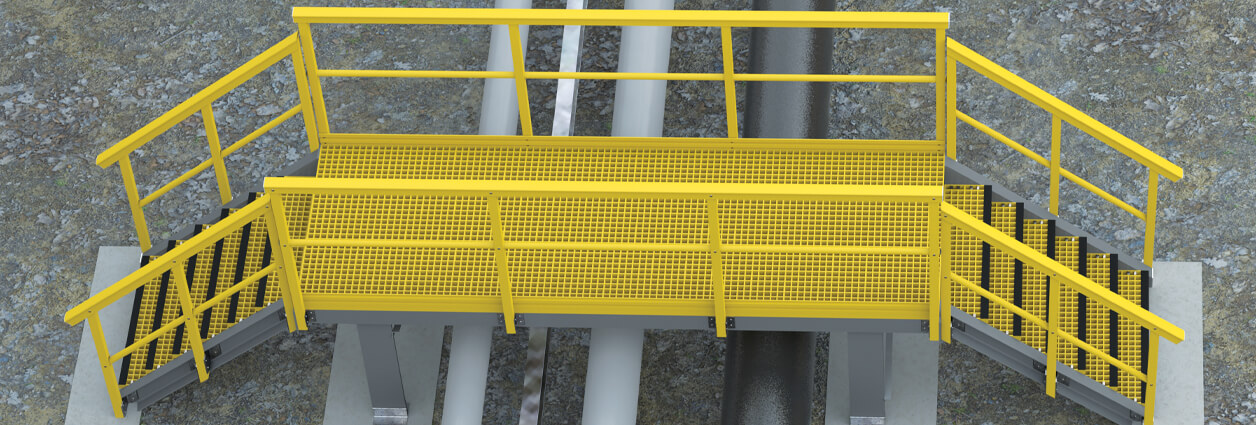

Our Glass Reinforced Plastic products deliver performance where it counts, ensuring long-term value and safety for your projects. We provide a comprehensive range of GRP Gratings, Anti-Slip Covers, and Structural Profiles designed to outperform metal and wood in the toughest environments, while offering simple installation and virtually zero maintenance.

Benefits to GRP Glass Reinforced Plastic Products

The GRP system delivers superior long-term value, safety, and operational efficiency compared to traditional materials.

Ultimate Corrosion Resistance

UV Stability

Extremely

durable

Incredibly Lightweight

Non-Conductive

Low Maintenance & Long-Lasting

Looking for a GRP handrail system?

The GRP Handrail systems from F.H.Brundle are designed to provide a secure and reliable means of support and guidance in various settings, such as staircases, walkways, platforms, balconies, and more. This type of handrail is well-suited for locations where safety, aesthetics, and functionality are important considerations.

Select your style

Mix and match components across your site for a complete, resilient GRP solution.

GRP (Glass reinforced plastic) gates have been designed for use with tube clamps and roof edge protection systems. Gate are supplied with hinges and latches, available in a yellow powder coated finish and comes supplies in two heights, 580mm high gate or a 1050mm high gate featuring a kick plate at the bottom.

Both can easily be cut to size on site for a perfect fit.

GRP (Glass reinforced plastic) Pultruded reinforcement bar is made from high strength glass fibre reinforced with vinyl ester resin. The core of the rebar has all the reinforcing fibre (70% by weight ) along the length of the bar for maximum strength.

The GRP reinforcing bar, made from high-quality fibreglass and vinyl ester resins, ensures long life and maintains the structural integrity of projects where it’s used. Compared to steel, the GRP reinforcement bar eliminates the risk of corrosion, a significant advantage in environments prone to chemical exposure.

A GRP (Glass Reinforced Plastic) also known as FRP (Fiberglass Reinforced Polymer) reinforcement bar is an excellent alternative to traditional steel reinforcement in construction. This reinforced bar offers over 50 years plus resistance to corrosive chemicals, making it a highly durable option for various applications.

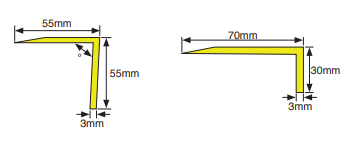

The excellent anti-slip properties provide increased safety on steps and stairs and the high contrasting colour aids visibility. The grit is embedded into a specially pultruded GRP profile which is resistant to swelling, stretching or warping. Its strength means that it will help cover lightly chipped stair edges making them safer whilst protecting the stair edge itself to further damage.

Fibre step nosing has been developed as a cost-effective, long-term solution to the obligations under the DDA Part 3 and in particular, the sections relevant to the partially sighted; in essence, all stairs accessible by members of the public, should have a contrasting coloured nosing fitted to the step edges and in addition, such nosing should provide a slip resistant top surface.

Available in two sizes, the 70 x 30mm is the standard and 55 x 55mm to meet current Building Regulations, with the maximum length of 3m, which can easily be cut on site

TYPE I

Type I with its smaller grit size is usually for internal use

TYPE E

Type E with a much heavier grit profi le is ideal for the rigours of the external environment.

Flat sheets have the same characteristics as our GRP stair treads and landing covers, providing a fast, safe and effective solution to slippery, worn or uneven flooring. The sheets ensure a highly visible, robust and durable slip resistant walking surface. Ideal for walkways, ramps, gangways or factory floors. GRP non-slip sheets are durable and easily applied, creating a safer flooring environment. We stock a variety of size panels all 4mm thick in black and yellow.

Available in two colours

Black

Yellow

As well as being versatile and cost effective, GRP gratings are lighter and more durable than steel, offering a high resistance to corrosion. They are fire retardant, chemical resistant and non-conductive with a high strength to weight ratio and require virtually no maintenance. GRP gratings are suitable for many applications, providing safe and cost-effective anti-slip flooring solutions where long term performance in aggressive corrosive or chemical environments is required.

Applications include:

When used vertically, GRP gratings can be used as debris and litter screens or machine guards.

• Pontoons

• Walkways

• Raised flooring

• Ramps

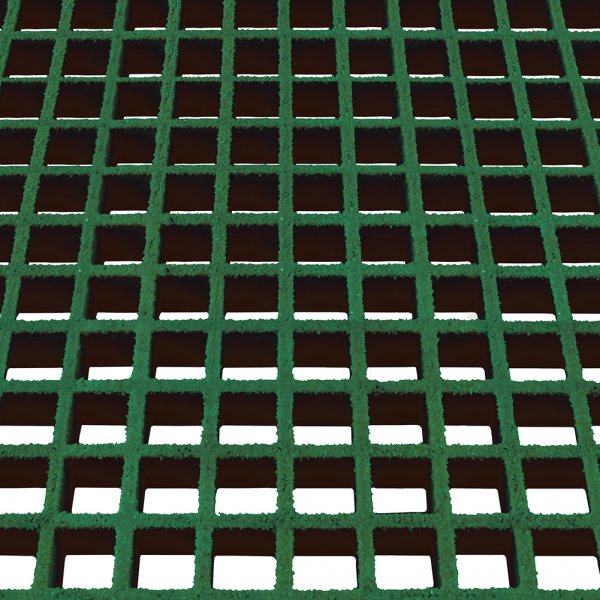

Available in four colours

Green

Grey

Sand

Yellow

GRP (glass reinforced plastic) as a material for stair treads offers many benefits. It is corrosion and slip-resistant and can withstand major impacts. It is much lighter than steel and improves safety by reducing the occurrence of slips and falls with its contrast gritted nosing

Tread Covers are a fast, convenient way of providing solid, slip resistant footing to existing stairs. The contrasting coloured nosing complies with the UK Building Regulations as applicable from May 2004 and those obligations required under the DDA. The tread cover is easy to install and can be applied to almost any surface including concrete, steel or wood.

Available in four colours

GRP (Glass Reinforced Plastic) flooring, plates, and stair treads outperform traditional materials by combining durability with high safety standards. It defies corrosion, grips to prevent slips, and absorbs major impacts without failing. Because it weighs significantly less than steel, GRP simplifies installation while proactively reducing workplace accidents.

This versatile material resists fire and chemicals, making it the ideal choice for demanding environments like gantries, ramps, and factory floors

Available in four colours

Green

Grey

Yellow

Red

GRP palisade fencing is rapidly becoming the product of choice among many industrial sectors and offers a unique solution for the likes of Network Rail and National Power and other industrial sites where they require a safe barrier system that is non-conductive and metal free, thus reducing the chances of any potential accidents due to electrical cross-over.

Non-conductive, lightweight and radar transparent, glass reinforced plastic (GRP) palisade fencing system meets the most demanding of performances.

Features:

- 1.8 & 3m fence heights

- Zero metal parts

- Lightweight

- Grey or green

- Non-conductive

- Long lasting

- UV resistant

- Adapts to slopes

- Single & double gates

GRP (Glass Reinforced Plastic) flooring delivers high-performance durability where traditional materials fail. It resists corrosion, prevents slips, and survives heavy impacts with ease. Despite weighing significantly less than steel, GRP actively improves site safety by eliminating common trip hazards.

From industrial gantries to factory floors, GRP provides essential fire and chemical resistance. Engineers trust it for walkways, ramps, and workstations across the most demanding environments.

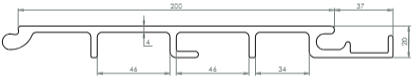

Deck 250 Board

Our GRP Deck 250 flooring boards boasts a unique interlocking board creating a seamless solid floor , allowing the system to be fitted quickly and easily. Supplied with a gritted anti-slip surface. Strong and lightweight.

Deck 500 Board

Our GRP flooring is a one-piece pultruded profile with a tongue and groove joint on the length of the plank that gives a firm, sealable joint and creates a solid floor with a gritted anti-slip surface. Strong and lightweight, it will span 1.5m at a design load of 5kN/m2 with a deflection limit of L/200.

GRP vertical access ladders are a safe, simple modular design offering individual parts which bolt together to form a complete ladder kit. It is flexible, easy to install and will solve virtually any access problem.

Ladder kits have been designed to offer an inexpensive, modular solution to permanent roof access installations and can be configured to suit any installation requirements. Manufactured in GRP yellow (Glass reinforced plastic), they are supplied with fall protection back hoops and with a range of entry and top exit options to suit all possible situations.

FAQs

GRP Glass Reinforced Plastic Products are used across multiple industries, including construction, marine, railways, electrical substations, chemical plants, and manufacturing facilities. Common applications include walkways, platforms, ramps, gantries, factory floors, pontoons, raised flooring, machine guards, roof access ladders, handrail systems, and perimeter fencing where corrosion resistance and safety are essential.

Yes, GRP products feature integrated gritted or concave surfaces that provide outstanding anti-slip traction, even in wet or oily conditions. GRP stair treads include high-contrast coloured nosing that complies with UK Building Regulations and DDA requirements, significantly reducing slip hazards and improving visibility for partially sighted individuals.

No, GRP requires virtually zero maintenance throughout its 50+ year service life. Unlike steel, it never needs painting, galvanizing, rust treatment, or protective coatings. It won’t rot like wood or corrode like metal, eliminating ongoing maintenance costs and making it the most cost-effective long-term solution.

GRP products are significantly easier to install than steel alternatives due to their lightweight nature (up to 70% lighter). They can be handled and installed without heavy lifting equipment, cut on-site using standard tools, and quickly adjusted to fit complex layouts. This results in faster installation times and reduced labour costs.

Yes, GRP is non-conductive and acts as both an electrical and thermal insulator. This prevents shock hazards and makes it ideal for electrical substations, railway environments, and any location where electrical safety is critical. Unlike metal alternatives, GRP eliminates the risk of electrical cross-over accidents.

GRP Glass Reinforced Plastic Products, also known as fibreglass or FRP, is a composite material made from high-strength glass fibres reinforced with vinyl ester or polyester resin. It offers superior corrosion resistance, durability, and strength compared to traditional materials like steel and wood, making it ideal for industrial, commercial, and public-sector applications.

GRP Glass Reinforced Plastic Products offer ultimate corrosion resistance, UV stability, and exceptional durability, while also being incredibly lightweight (up to 70% lighter than steel). They’re non-conductive, making them safe for electrical environments, require virtually zero maintenance, and have a service life of 50+ years. GRP also provides superior anti-slip properties and can be easily fabricated on-site using standard tools.

While GRP Glass Reinforced Plastic Products may have a higher initial cost than steel or aluminium, it delivers a lower total cost of ownership due to zero maintenance requirements, complete rust resistance, and a 50+ year lifespan. GRP eliminates the need for painting, galvanizing, or frequent repairs, is up to 70% lighter for easier installation, and won’t corrode in harsh chemical or marine environments.

Yes, GRP is exceptionally well-suited for outdoor and marine environments. It’s completely resistant to salt water, rust, rot, and UV degradation. GRP remains unaffected by extreme heat, cold, or continuous sun exposure, making it perfect for pontoons, walkways, coastal installations, and any application exposed to harsh weather conditions.

F.H. Brundle offers a comprehensive range of GRP products, including gratings (in green, grey, sand, and yellow), stair treads and covers, structural profiles (angles, I-beams, channels, tubes), handrail systems (round and square), anti-slip nosing, flat sheets, decking boards, ladders, palisade fencing, reinforcing bars, and safety gates.