Balustrade and railings

For use with Outdure QwickBuild framing

When installing a deck, it’s important to consider whether that deck will require balustrade or railing. If the drop is over 600mm, UK building regulations (Part K) insist you use it. If the drop is under 600mm then adding balustrade or railing is purely an aesthetic choice. If you are looking to add it, our range of balustrade and railing systems offers the ultimate selection.

The following will introduce you to those options and explain how balustrade can be fixed to an Outdure Qwickbuild deck frame.

Premium porcelain tiles from

ex VAT

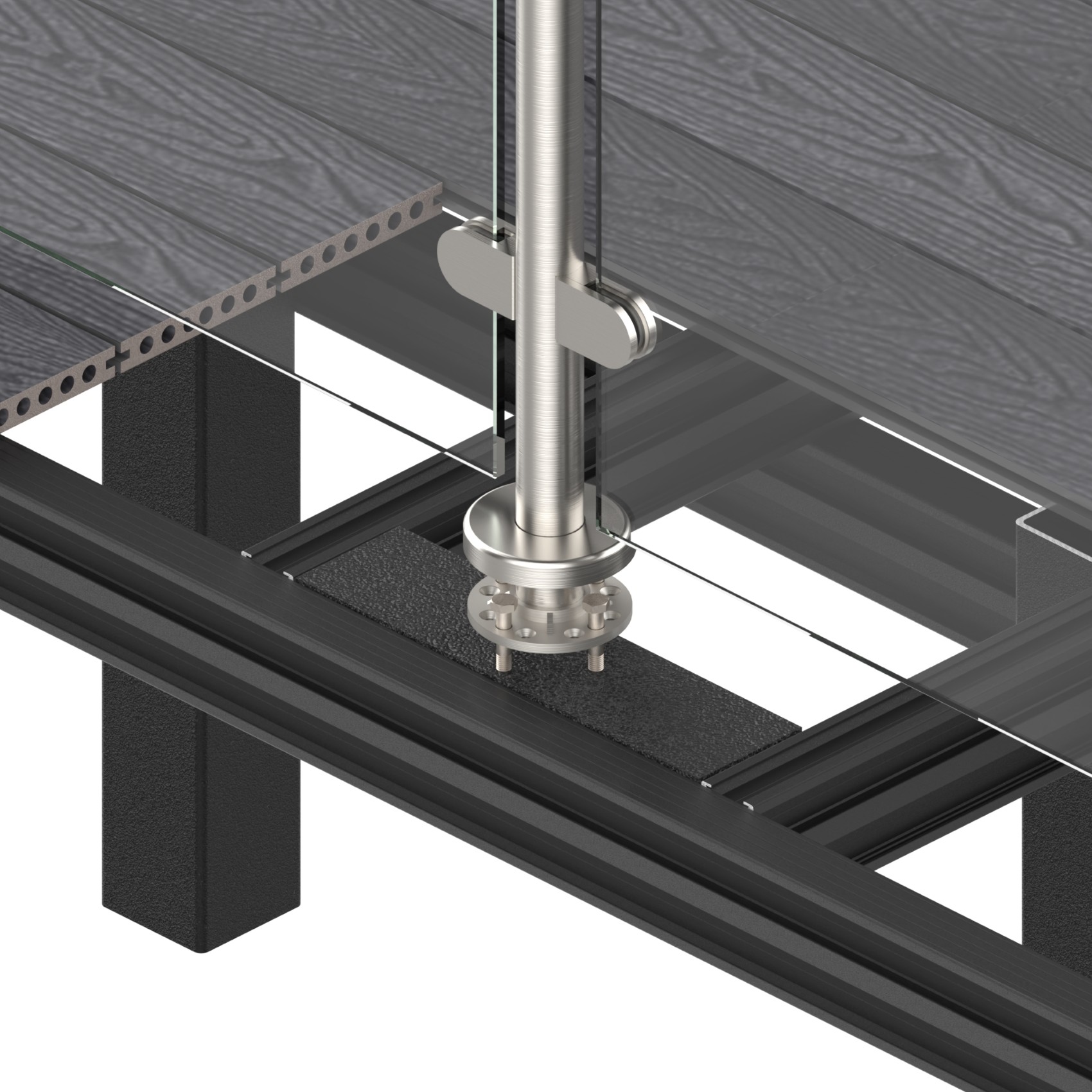

Constructing your deck frame for balustrade

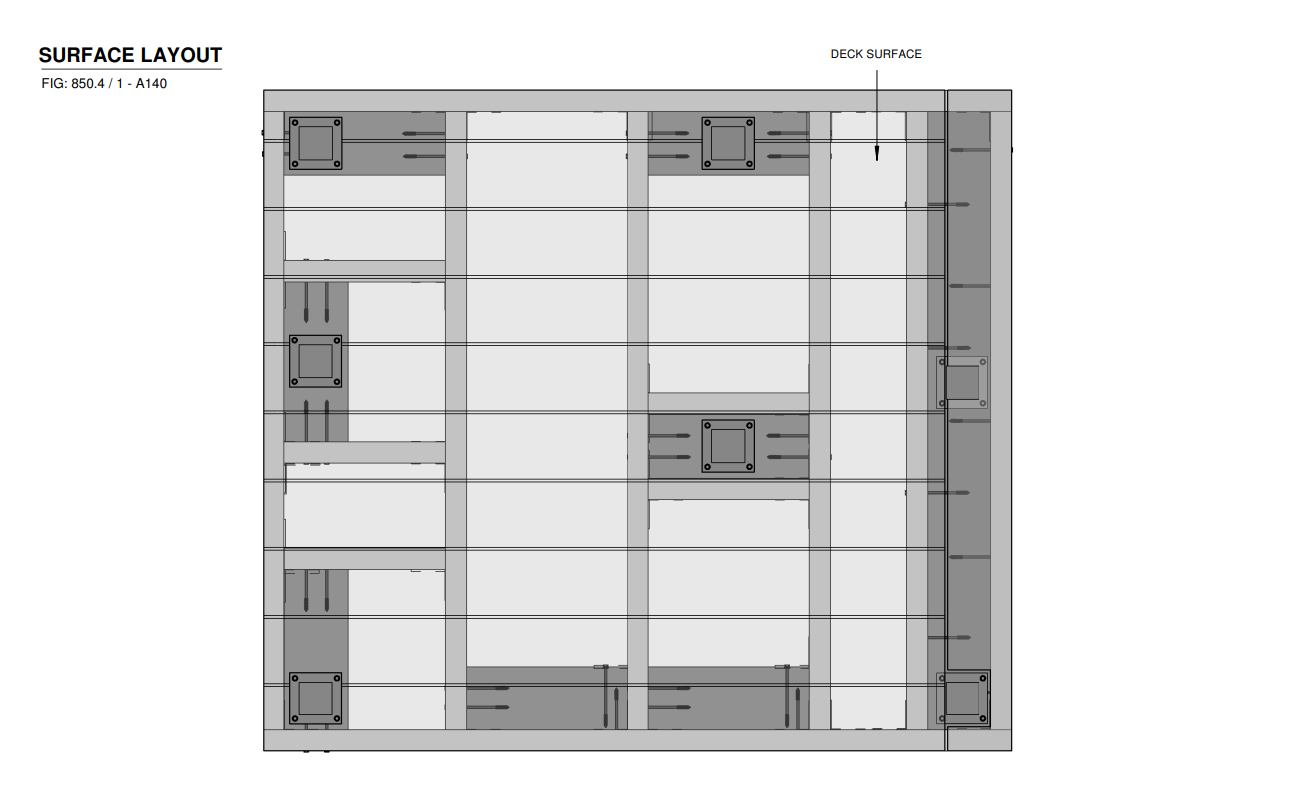

As with any deck, it is important to first create an accurate plan of your Outdure® deck when installing balustrade. With most other decking systems, having to retrofit a subframe to take balustrade, is costly and sometimes requires a complete rebuild. That, however, is not the case with Outdure QwickBuild, but it is still recommended to allow for railing or balustrade at the point of installation.

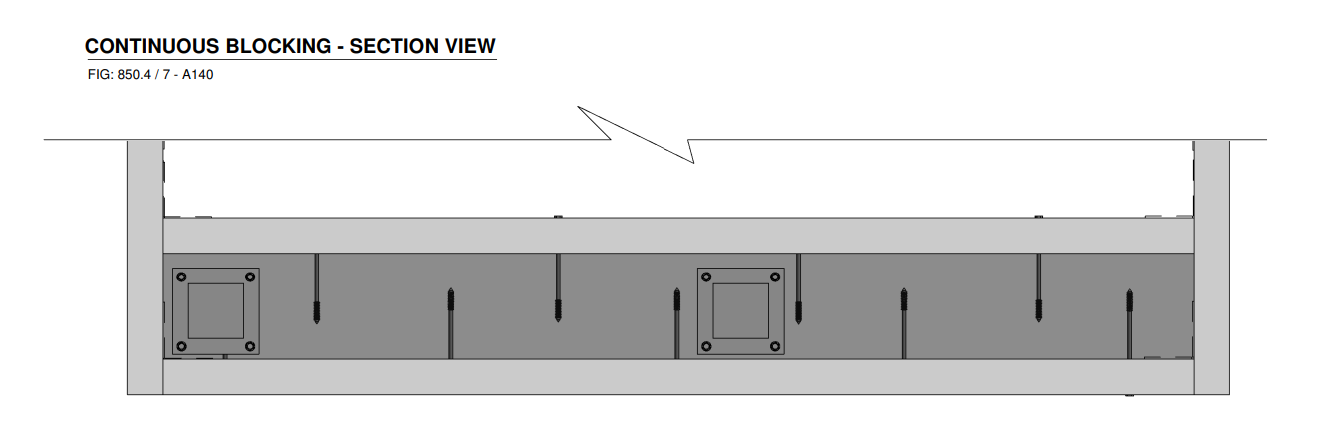

When creating your design/plans, allow for blocking to be added to the perimeters of the deck where balustrade or railing is to be added. Blocking provides a structural foundation, supplying the strength and support required when fixing any balustrade system. Never fit a balustrade or railing where blocking is not in use.

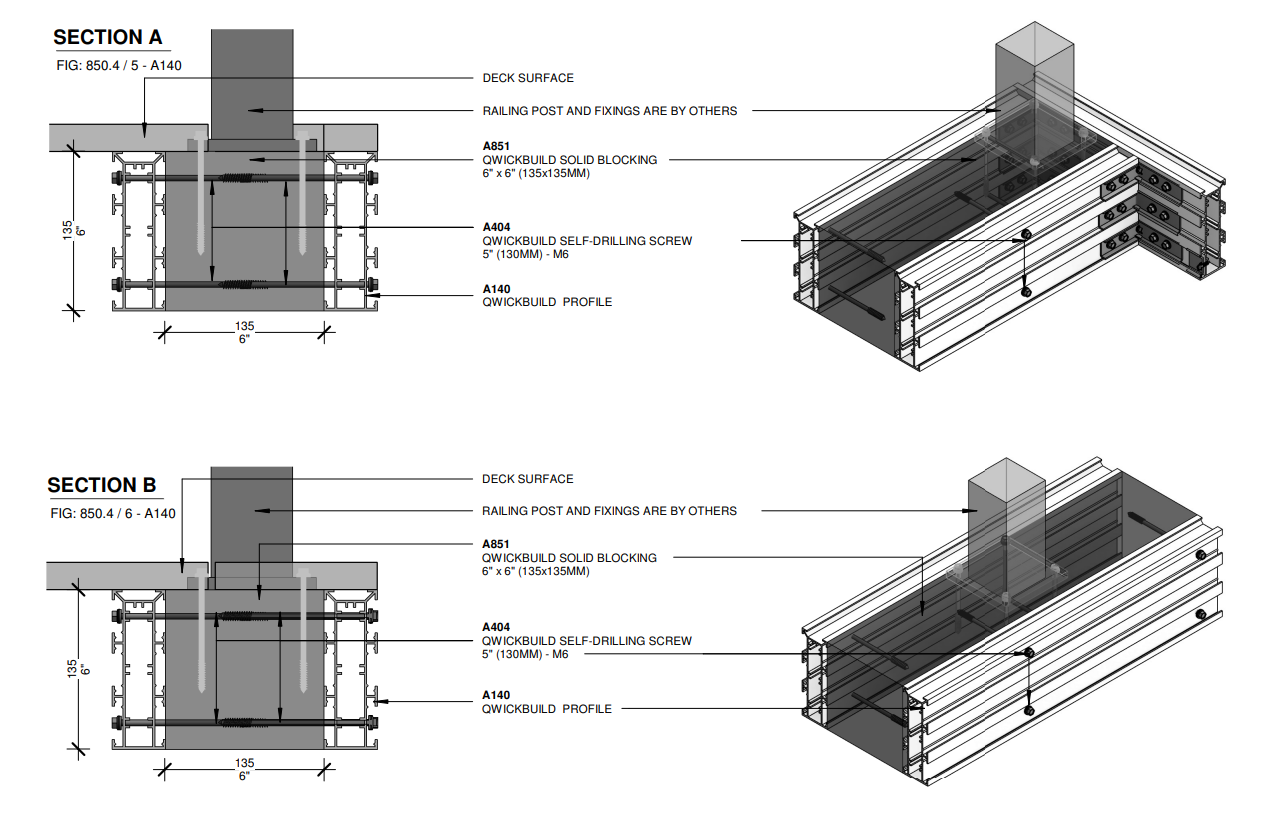

Outdure QwickBuild is designed to integrate a structural polymer block of 135mm width.

Please note that balustrades and railings should only be fitted to an Outdure system when the A140 (135mm deep) or A150 joists are being used.

Polymer blocking

135 x 135 x 350mm Blocking

Pre-cut to 350mm to fit 400mm joist centres. Manufactured from 100% recycled plastics and structurally tested.

Suitable for top-fix post and spigot balustrade systems and side-fix balustrade systems.

This product is also available in a

3600mm length

Side-fix balustrade and railing solutions

Side-fix, fixing from the vertical face or perimeter face of the decking into the subframe, is typically used when aiming to maximise the surface area of the deck or where the fixing method wants to be hidden or discreet. In any instance of using a side-fix system, we recommend using the 135mm polymer blocking for added structural support.

Notice: Liveconfigurator will not provide you with installation instructions for your chosen system.